Soft robotics, a rapidly expanding field with the potential to revolutionize various industries, utilizes highly flexible materials to enable robots to perform tasks that conventional rigid robots cannot. These soft robots excel in confined spaces, hazardous environments, and interactions with people and objects due to their versatility.

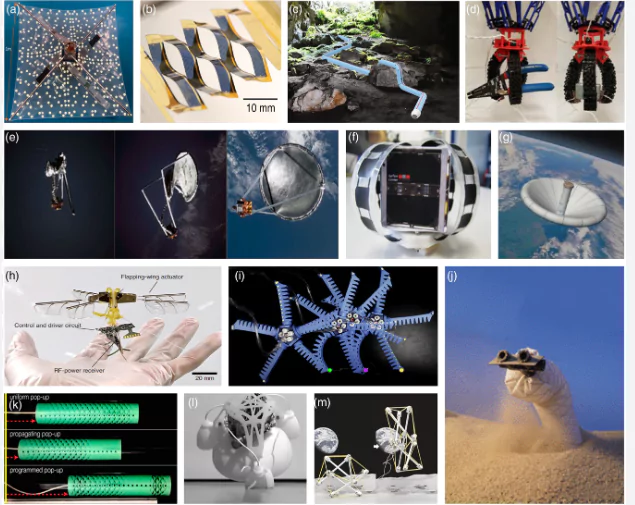

The growth of soft robotics in the past decade can be attributed to advancements in manufacturing techniques that allow the creation of complex multi-material robots. While numerous articles showcase various soft robot designs, distinguishing meaningful innovations from mere modifications is crucial for the future of this field.

Advances in Soft Robotics Research:

In recent breakthroughs, different research institutions have made significant strides in soft robotics:

- Engineers at the University of California, Berkeley, have crafted self-healing soft robots, utilizing microcapsules containing therapeutic agents for repairs.

- Researchers at MIT have introduced “adaptive soft robots” that learn from experiences and employ machine learning algorithms to enhance performance.

- Harvard University scientists have developed biologically inspired soft robots, mimicking biological motions using pliable materials actuated by fluid pressure.

- Scientists at the University of Washington have engineered biocompatible soft robots suitable for human tissue, ensuring no adverse reactions upon insertion into the body.

Soft robotics has witnessed remarkable progress, offering exciting possibilities for future applications and innovations, especially in areas like robotics for kids, where safe and adaptable designs are crucial for education and engagement.

Soft Robotics: The Historical Evolution and Current Milestones

Seventy years ago, McKibben’s compliant actuators laid the foundation for soft robotics, evolving into inflatable actuators that enable the creation of fully flexible robots. The field of bio-inspired robotics achieved a significant milestone with a robot navigating the Mariana Trench autonomously, showcasing complete flexibility and autonomy.

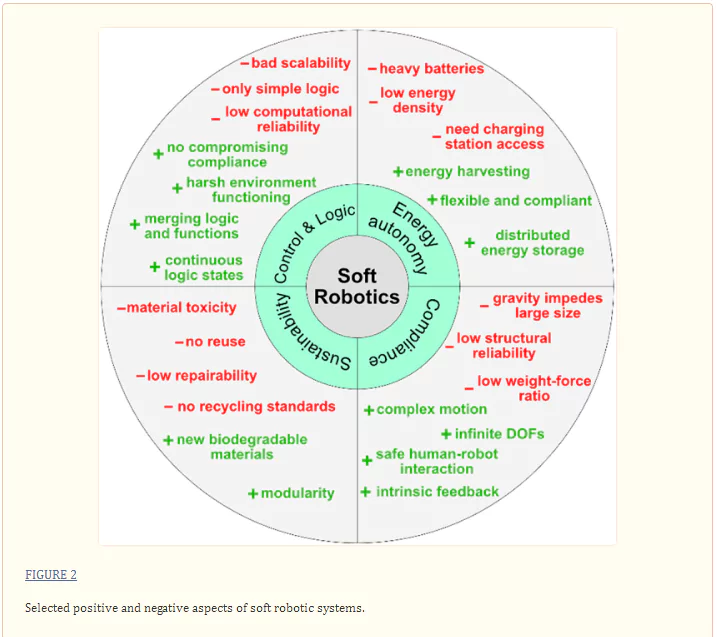

This perspective paper, authored by young researchers, addresses the inherent contradictions within fully flexible autonomous systems. It explores the need for electronic controls, onboard energy supply, sustainability, and other critical issues in bio-inspired soft robots, proposing potential solutions and highlighting less-explored application areas.

Soft Robots vs. Traditional Robotic Systems

Soft robots, constructed from flexible materials using techniques like 3D printing, offer promise in various applications. They utilize compliant pneumatic actuators, ensuring safety in human-robot interactions and adaptability in challenging environments. However, their ability to generate sufficient force and handle larger tasks remains a challenge. The balance between compliance and functionality in larger soft robots raises questions about their scalability and potential risks to humans.

Feasibility and Utility of Electronics-Free Soft Robots

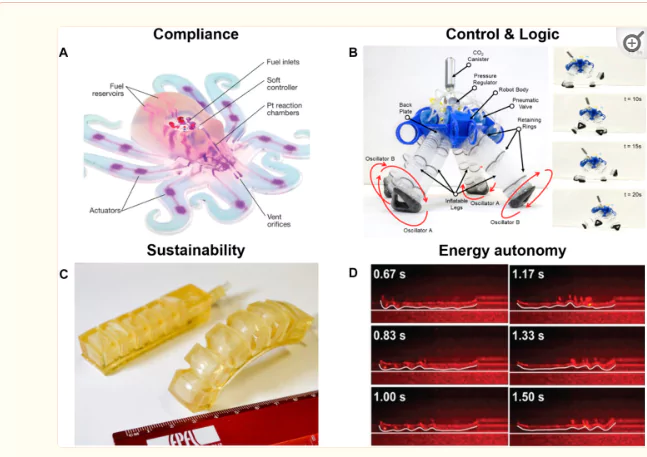

The feasibility of soft robots operating without electronics is a crucial aspect. While electronics can compromise compliance in soft robots, examples like the Octobot demonstrate sensing and decision-making without electronic components. Innovative electronic-free soft logic gate systems use pneumatic pressure and basic logic gates, while bio-inspired plant robotics respond to stimuli and harness environmental energy.

Fully electronic-free autonomous soft robots may have limitations, primarily suitable for specific, repetitive tasks. Achieving a paradigm shift in soft robotics may require integrating soft and traditional electronic components while exploring new materials to enhance durability.

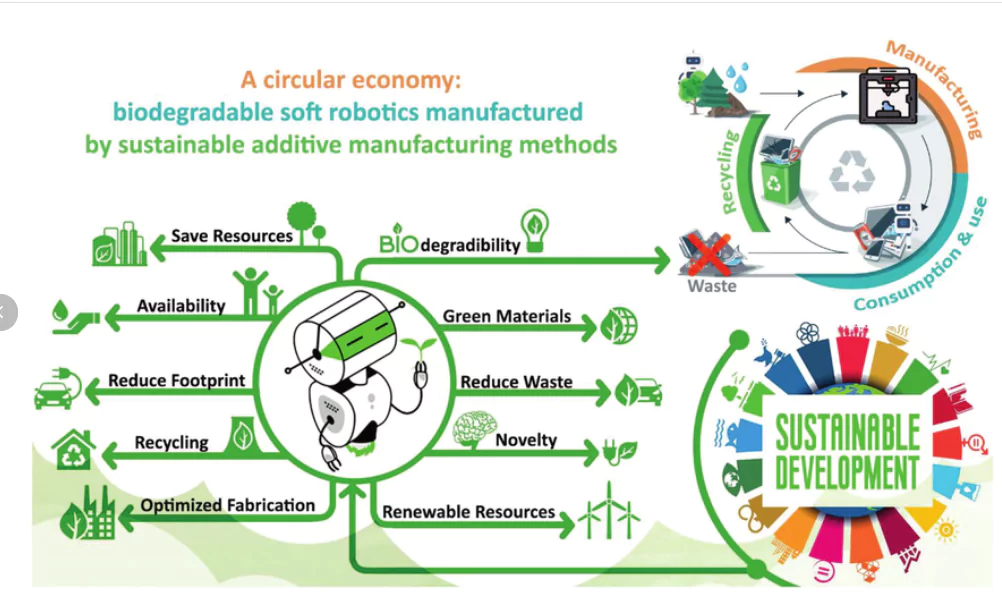

Sustainability of Soft Robots in the Circular Economy

Integrating sustainability into soft robotics is essential, aligning with the goals of a circular economy. The recyclability of electronic components poses a challenge, although some soft robot materials are biodegradable. To enhance recyclability, individual robot materials should be easily separable. Utilizing recyclable and sustainable materials can unlock new applications in medicine.

Recommended Reading: How Coding Skills Prepares Kids For Tomorrow’s Jobs

Can Soft Robots Operate Without Power Packs?

Energy is fundamental for robotic task execution, but accommodating energy storage and delivery complicates autonomy. Soft robots diverge from traditional robots due to the bulkiness of batteries. Alternative energy supply approaches include controlled external fields and storing energy within the robot’s body. Self-powered sensors and sensory systems driven by energy harvesters offer potential, but the challenge lies in matching energy consumption with supply.

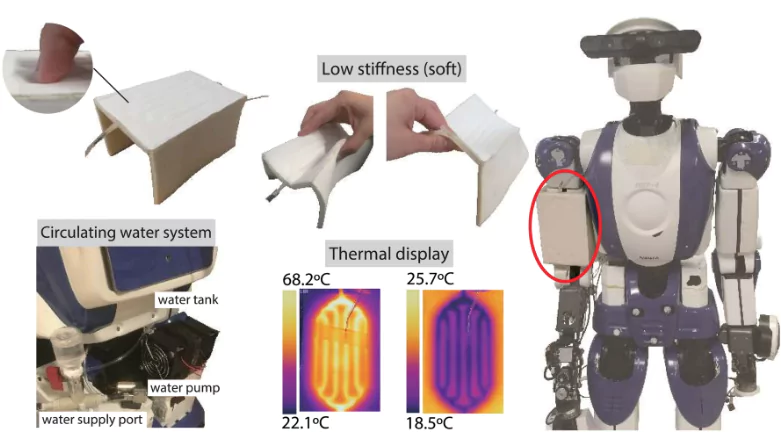

The Future of Autonomous, Sustainable Bio-Inspired Soft Robots as Artificial Organs

Soft robots offer sustainability and adaptability, making them promising candidates for artificial organs. The urgent need for such systems becomes evident given the shortage of organ donors. Creating autonomous, electronics-free, sustainable, and biocompatible artificial organs addresses these challenges, offering practical solutions to the demand for organ transplants. Advancements in actuation technology, sustainable materials, and customization techniques can improve the lives of patients awaiting organ transplants.

Recommended Reading: 10 Best Coding Books Your Child Should Read

The Technology of Soft Robots

Similar to the evolution of modern portable gadgets compared to their bulkier predecessors, soft robots have abandoned the rigid structures of older heavy machinery robots. These modern robots can alter their shape and size, conform to objects, interact safely with humans, and delicately handle items as fragile as a tomato.

As per the SRI Robotics Program, 4 key technologies are instrumental in this evolution:

1. Electroactive Polymer

Electroactive Polymers, also known as artificial muscles, expand and contract in response to applied voltage, converting electrical energy into mechanical motion. This technology allows robots to move with human-like dexterity, change surface texture, and develop skins capable of sensing pressure and contact. These polymers find applications in wearables, embedded in clothing and fabrics to measure motions and forces, catering to various needs for soft, flexible, and electrically-active actuation and sensing.

2. Soft Grippers

Unlike rigid grippers, soft counterparts require minimal sensing and control to grasp objects. For instance, jamming grippers use a flexible sack filled with a powder-like substance, conforming to objects of any shape. A vacuum process then makes the gripper rigid, allowing it to grasp objects through friction without complex processing.

3. Electro adhesion Technology

This technology utilizes electrostatic forces to pick up delicate objects where frictional forces are insufficient. Similar to the electrostatic attraction created by rubbing a balloon on hair, this method allows gripping various objects. SRI’s application of this technology has led to wall-jumping robots capable of working on damp or rough surfaces.

4. Electro Laminate Technology

Electro Laminates enable materials to transition from soft to hard on demand without adding significant bulk, mass, or power. Using low-cost and lightweight flexible polymers, this technology provides great stiffness variation and elongation with quick reaction. Integrated with MIT’s FitSocket technology for prosthetic limbs, the electro laminates in the straps connect human bodies to the prosthetics, becoming rigid during motion and flexible at rest.

Notable Soft Robotics Projects

1. Octobot

Harvard University’s Octobot, inspired by an octopus’s structure, is the world’s first entirely soft and autonomous robot. Utilizing embedded 3D printing, molding, and soft lithography, this robot operates without rigid components, using a pneumatic mechanism powered by gas under pressure, controlled by a logic circuit.

2. Caterpillar Micro-Robot

Researchers at the University of Warsaw developed a bio-inspired microrobot resembling a caterpillar in appearance and movement. This soft robot can travel, climb, and carry loads due to its unique body made of a light-sensitive elastomer stripe with patterned molecular alignment.

3. Exo-Glove Poly

Developed by Professor Kyu-Jin Cho from Seoul National University, this device operates as a grip augmenting device between a wearable gadget and a prosthetic limb. Waterproof and user-friendly, it facilitates hand and finger movement using simple actuators and wires, benefiting individuals with paralyzed hands.

4. SNUMAX

A multi-functional soft robot developed by Biorobotics Laboratory, School of Mechanical & Aerospace Engineering, and Seoul National University, SNUMAX won the RoboSoft Grand Challenge. It features transformable origami wheels and a soft manipulator, enabling flexible and safe movements, along with an adaptive gripper for grasping various objects through an adaptive positioning mechanism.

These remarkable soft robotics projects illustrate the innovative and diverse applications of this technology, showcasing its potential in various fields and challenging environments.

Conclusion

Soft robotics is a fast-growing discipline that has the potential to completely transform a wide range of applications and industries. Soft robots are perfect for jobs requiring interaction with people or delicate things since they are safer, more flexible, and more dexterous than standard robots. We should anticipate seeing a growing number of soft robots in our daily lives as technology advances.

Moonpreneur is on a mission to disrupt traditional education and future-proof the next generation with holistic learning solutions. Its Innovator Program is building tomorrow’s workforce by training students in AI/ML, Robotics, Coding, IoT, and Apps, enabling entrepreneurship through experiential learning.

My 10-year-old daughter was fascinated by Octobot’s soft robotics and autonomous navigation. She’s now exploring robotics courses. Thanks for inspiring the next generation.

As a robotics engineer, I suggest you add some success stories of students who excelled in their career by the way of soft robotics. It would be more helpful to encourage the next generation to opt this field.