Unleashing the Power of Industry 5.0 & Transforming the Way We Work

From the 3.0 industrial revolution to the 4.0 industrial era, and now we are moving into the 5.0 industry. Industry 5.0 is more human-centered than ever before. It is not just about new technologies; it is a major transformation of how we innovate with human centricity at its core. This era dwells on the synergy between humans and machines. The aim is to balance technological breakthroughs with societal demands. Corporations should adjust in order to compete successfully within this context of change. This shift matters for sustainability and inclusiveness because that’s the point where we need every one of us to come on board for things to work out well.

Evolution of Industry

Industries all over the globe have continuously revolutionized themselves through different industrial waves of change and development. Industry 4.0 phase involves the use of cloud computing solutions to gather and manage large volumes of information with future value chains backed by big data analytics. Industry 4.0 is estimated to generate up to $3.7 trillion in value by 2025, as per a report published by McKinsey.

Essentially, Industry 4.0 is regarding the idea of process automation and the incorporation of edge computing that involves key elements like sensors and actuators for creating smart systems, generating digital twins, and providing highly optimized products and operations.

Industry 4.0 has created the basis for development of a new paradigm, which is called Industry 5.0. It is a highly developed technological environment that enables interaction of machines with the creativity of the people. The central focus is on people, productivity, and the principles of sustainability & personalization. The survey, conducted by PwC, reflected that 72 percent of international businesses plan to increase their investments in human-machine collaboration technologies in the near future. Industry 5.0 aims to improve the functionalities of intelligent systems through human intervention. This goes to depict that we are preparing for the next industrial revolution where man will solely depend on machines to push industries to higher standards. The cobot is a good example of this shift in manufacturing; the market size of which is expected to grow from $1.9 billion in 2024 to $11 billion by 2030.

Important Insights of Industry 5.0

| Key Statistic | Data/Explanation |

|---|---|

| 4 times faster learning with AR/VR | According to the Data Bridge Market Research analysis, Virtual reality learners acquire skills 4 times faster than in a regular classroom. |

| $48 billion worth of Digital AR/VR | Projected value of the global digital twin market in 2026, reflecting a compound annual growth rate of 58% from $3 billion in 2020 (Siemens). |

| 4% Current Injury Rate without Robots | The cost of workplace injuries is estimated at 4% of the world's GDP, according to the International Labour Organization. Robots and cobots will lower the number of injuries. |

| 50% Increase in productivity through Cobots | The use of cobots in various industries has led to an increase in productivity of up to 50%, without disrupting human labor. |

| Robots will Create 133 Million New Jobs | Robots are expected to displace 75 million jobs globally by 2022 but will create 133 million new ones - a "net positive" according to the Swiss think tank. |

| 2.32 million occupations will be AR/VR-based | It is anticipated that 2.32 million occupations in the United States will include AR or VR by 2030 (Data Bridge Market Research). |

Real-world Industry 5.0 Case Studies

Many industries today are already experiencing benefits from the innovation of Industry 5.0:

- Automotive: Currently, in automotive manufacturing, industries such as BMW use cobots on the production line, which saw an enhancement of production by 15% and a decrease in the rate of errors by 20%. Toyota installed artificial intelligence for quality control and incorporated real-time monitoring programs for the quality enhancement of its products by 20% and for reducing defects by 15% in the production line.

- Healthcare: Machine learning based models have the capabilities of providing an accuracy of 95 percent for the overall survival rates-benchmarks.

- Consumer Goods: Individualization is now forthcoming, large companies such as Nike are integrating AI to provide customized products, thus increasing a customer’s satisfaction by 25 %.

- Supply Chain: Coca Cola used AI-driven demand forecasting for its supply chain where it enhanced lead times by 50% and cut its inventory expenses by 45%.

- Waste Management: Real-time monitoring of machines 50% waste was reduced through implementing real monitoring machines and predictions.

- Beverage: Coca-Cola’s Hellenic Bottling Company applied smart energy management with IoT sensors and analysis supported by AI at its plants, achieving 30% of energy loss.

What Does Industry 5.0 Mean For Your Strategy?

Industry 5.0 is an emerging concept that builds upon the previous industrial revolutions, particularly Industry 4.0. While Industry 4.0 focused on automation, data exchange, and advanced manufacturing technologies, Industry 5.0 emphasizes the integration of humans and machines, particularly in collaborative and symbiotic ways.

For your strategy, Industry 5.0 suggests a shift towards more human-centric approaches to technology and manufacturing. Here are some considerations:

- Human-Machine Collaboration: The role of AI and robotics, in Industry 5.0, is seen as complementary to rather than a replacement for human employees. According to the present market analysis, the market of cobot is estimated to expand at a CAGR of 34.3%. By 2029, cobots should make up a huge part of the industrial market because innovation in the workplace requires dramatic advances that embedding these intelligent machines into commercial processes provides.

- Sustainability and the Green Transition: In line with the European Green Deal, Industry 5.0 stresses on responsibility towards environment and humans in production procedures. Including cobots to take over dangerous operations or tasks that would otherwise lead to severe injury or loss of life can help minimize the cost of workplace injuries since it amounts to approximately 4% of the total global GDP.

- Resilience and Adaptability: Industry 5.0 makes industries more resilient by leveraging advanced technologies and adaptive strategies. Reports from organizations like the World Economic Forum highlight the growing demand for skills in areas such as data analysis, digital literacy, and human-machine interaction.

Industry 5. 0 helps industries become more ready to withstand potential challenges through the proper use of various technologies and methods. According to reports from such organizations as the World Economic Forum, there are some skills which are gaining demand in the international economy such as data analysis, digital skills, and interaction between human beings and machines.

Digitalisation: Key Driver of Industry 5.0

Currently, digitalisation is at the core of establishing Industry 5.0 forward, with benefits like Cloud, IoT, AI, and Data Analytics emerging as key components of the manufacturing industry. The estimated rise in the digital twin market to $48 billion by the end of 2026 also demonstrates the expansion of the role of digital technologies in improving operational performance and creating new solutions and ideas.

Applications of Industry 5.0

Recommended Reading : Generative AI in Healthcare: Bridging the Gap Between Data and Diagnosis

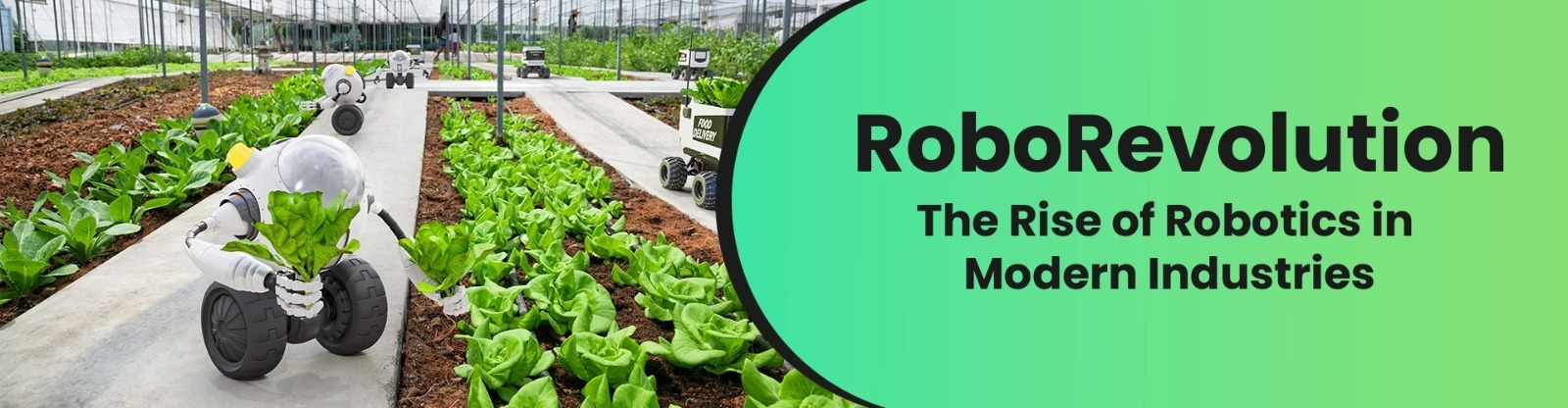

- Manufacturing Industry: Intelligent and hybrid environments, where human and machines work in harmony, will help increase productivity and efficiency in manufacturing industries. By 2029, the cobots will become a major part of the intelligent manufacturing space for sustainable development and growth.

- Production in Manufacturing: Agile production lines, supported by human-centric design principles, will enable rapid adaptation to changing demands and product variations. With the projected growth of the global digital twin market to $48 billion by 2026, leveraging digital twins becomes essential for enhancing production efficiency and innovation.

- Supply Chain and Logistics: Technological advancements such as real time tracking and predictive supply chain analytics will further improve efficiency and cut down on excess carrying costs and unnecessary resource allocation. The market containing cobot products will increase at the rate of CAGR 34. By 2029, it will be essential to innovate in supply chain and logistics by including cobots up to 3%, which will help improve the processes.

- Healthcare Industry: Industry 5.0 will profoundly influence the healthcare sector by making it possible to administer customized therapies and to facilitate interoperability between doctors and machine learning algorithms. With improvements in medical diagnostic tools and use of Artificial Intelligence in discovering new drugs it’s Industry 5. That is interesting as it can potentially revolutionalise patient care and treatment outcomes.

Future with Industry 5.0

The future with Industry 5.0 promises a paradigm shift in how we conceptualize and implement technology in various aspects of our lives, work, and society. Here’s a glimpse into what the future might hold with Industry 5.0:

Human-Machine Symbiosis:

Industry 5.0 symbolizes a world where humans and technology are entangled in cooperative partnerships and are dependent on each other in achieving more output, higher returns and creativity. This could include next-gen co-creation, where machines augment humans to present profound choice-making, innovation and resolution-finding for better meaningful results in diverse sectors.

Responsible Automation:

Even though automation is the cornerstone of the fifth industrial revolution, it is not capable of replacing all human labor. There is also an increased awareness on ethical, social, and environmental issues as pertains to the implementation of AI. Businesses are more conscious of the challenges that automation brings to employment, sources of income, and societies, and are eager to find the ways on how technology can benefit people and complement their development. There is the need to objectively consider various factors including effects such as displacement at work, skills, and technology distribution.

Sustainable and Green Technologies:

Industry 5.0 aligns closely with sustainability goals, fostering the development and adoption of technologies that promote environmental stewardship and resource efficiency. From the real sustainability in power distributions of renewable energy systems and smart grids to environmentally sustainable manufacturing techniques and the circular economy business models, Industry 5.0 forward drives innovation towards a more sustainable future that can weather the tempest. This will include using ICTs in monitoring of environment, conservancy and climate change adaptation.

Personalized Experiences:

With Industry 5.0, there’s a growing emphasis on personalized experiences tailored to individual needs and preferences. As advanced technologies including artificial intelligence, data analysis, and robotics are used, they can deliver personalized commodities, services, as well as communication experiences that meet the specific needs of each client. It is stretching to the domain of personalized needs such as personalized healthcare, personalized education, personalized entertainment and so on.

Agile and Adaptive Systems:

In the future with Industry 5. 0, organizations value flexibility and adaptability as cardinal business success factors particularly in an evolving landscape. This makes it easy for companies adopting the agile manufacturing solutions and supply chain mechanisms for business to adapt to future market changes, customer needs, and trends. Another aspect of this agility refers to the flexibility of workforce dynamic, where employees are prepared on how to respond to changing nature of work and innovation.

Empowered and Inclusive Communities:

Industry 5. 0 will enrich people’s lives as well as communities by providing them with equal possibilities or resources in the modern world. Through digital inclusion initiatives, education programs, and community engagement efforts, Industry 5.0 fosters a more inclusive society where everyone can participate in and benefit from the digital transformation. This inclusivity extends to diverse populations, ensuring that technology serves the needs of people from all backgrounds and abilities.

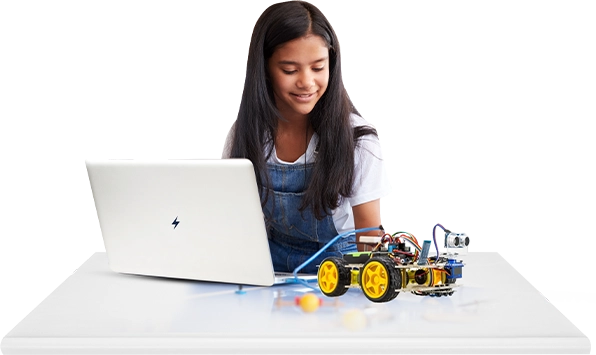

Preparing the Next Generation for Industry 5.0

Preparing the next generation for Industry 5.0 involves equipping them with the skills, knowledge, and mindset needed to thrive in a rapidly evolving technological landscape. Here’s how we can prepare the next generation for Industry 5.0:

- STEM Education: Emphasize STEM (Science, Technology, Engineering, and Mathematics) education from an early age to develop foundational skills in critical thinking, problem-solving, and digital literacy. Integrate coding, robotics, data analytics, and other emerging technologies into the curriculum to foster hands-on learning and experimentation.

- STEAM Integration: Expand STEM education to include the arts (STEAM), encouraging creativity, innovation, and interdisciplinary thinking. Incorporate design thinking, arts, humanities, and social sciences into the curriculum to develop well-rounded individuals capable of tackling complex challenges and driving innovation in Industry 5.0.

- Digital Skills Development: Provide opportunities for students to develop digital skills relevant to Industry 5.0, such as programming, data analysis, artificial intelligence, cybersecurity, and human-computer interaction. Offer coding classes, hackathons, robotics competitions, and online learning platforms to cultivate technical proficiency and confidence in using digital tools and technologies.

- Experiential Learning: Foster experiential learning opportunities that enable students to apply theoretical knowledge in real-world contexts. Collaborate with industry partners to offer internships, apprenticeships, mentorship programs, and project-based learning experiences that expose students to Industry 5.0 technologies, practices, and challenges.

- Soft Skills Development: Emphasize the development of soft skills such as communication, collaboration, adaptability, empathy, and resilience. Incorporate teamwork exercises, leadership development programs, cross-cultural experiences, and emotional intelligence training to prepare students for the collaborative and dynamic nature of Industry 5.0 workplaces.

- Ethical and Social Responsibility Education: Integrate ethical considerations and social responsibility education into the curriculum to foster ethical leadership, responsible decision-making, and civic engagement. Discuss the ethical implications of technology, such as privacy, bias, equity, and environmental sustainability, and empower students to become ethical stewards of technology in Industry 5.0.

- Lifelong Learning Mindset: Cultivate a lifelong learning mindset by promoting curiosity, adaptability, and continuous self-improvement. Encourage students to embrace change, learn from failures, seek out new opportunities, and stay abreast of emerging trends and developments in Industry 5.0 through self-directed learning, online courses, professional development workshops, and networking events.

Do you know? Student-Centered Learning: The Future of Education

Pioneering a Path to Future Success

As mentors guiding our children’s educational journey, let’s embrace the spirit of Industry 5.0 with unwavering determination. Encourage your child to embark on a voyage of discovery, where curiosity ignites learning, and hands-on experiences cultivate innovation.

At Moonpreneur, we recognize the changing landscape and the pivotal role of preparing the next generation for the challenges and opportunities ahead. That’s why we’ve curated a program designed to equip young minds with the skills and mindset essential for thriving in the future workplace. Introducing the Innovator Program, where your child will explore cutting-edge concepts such as robotics, emerging technologies, and forward-thinking strategies. Our curriculum transcends conventional education, fostering creativity, critical thinking, and adaptability—the cornerstones of success in Industry 5.0.

Book a Free Trial: https://moonpreneur.com/book-a-free-trial/

In embracing the ethos of Industry 5.0, we embark on a journey of infinite possibilities, where innovation knows no bounds, and every challenge becomes an opportunity for growth. As we unlock the potential within each child, we sow the seeds of a future where creativity, collaboration, and compassion reign supreme.

So let us dare to dream, to innovate, and to pioneer new paths forward. For in the heart of every child lies the power to shape a world where humanity and technology coexist harmoniously, where progress is synonymous with sustainability, and where the brightest of futures await.

Together, let’s illuminate the way towards a tomorrow where every child’s brilliance shines brightly, guiding us towards a future filled with promise and purpose.

I still have that memory in mind when my child built the first mini robot using a kit. That was an incredible sight to watch how wonderfully he expressed his excitement when the robot moved. Today, indeed, looking ahead into the future, when robotics is evolving so rapidly, it’s exciting to imagine the way children would be seen using robots in their day-to-day lives.

That was indeed a revelation just a few days ago at the workshop by Moonpreneur Robotics. Wow! Things have changed so much even for a starter robot, it really has some AI components. I imagine the wonders of what kids will dream up today and make a reality a few years down the line.