The food industry is undergoing a massive transformation, and at the heart of this change is robotics. From sorting vegetables and packaging snacks to ensuring hygiene and quality control, robots are revolutionizing how food is produced and delivered. The rise of robotics in food processing is not just about efficiency—it’s about safety, consistency, and meeting the growing demand for high-quality food.

Why Robotics is Entering Food Processing

The global food industry faces challenges such as labor shortages, increasing demand, and the need for strict safety standards. Robotics offers a solution by automating repetitive and time-consuming tasks. Robots can work around the clock, reduce human error, and handle delicate processes like cutting, cleaning, and packaging with high precision.

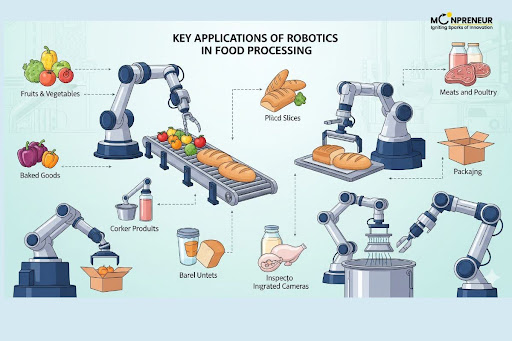

Key Applications of Robotics in Food Processing

1. Sorting and Grading

Robots equipped with advanced sensors can quickly identify the size, shape, and quality of fruits, vegetables, and grains. This ensures uniformity and reduces waste, helping producers maintain strict quality standards.

2. Cutting and Preparation

Precision is critical when it comes to slicing meat, cheese, or baked goods. Robotic arms with laser-guided systems can perform cutting tasks more accurately and safely than manual labor.

3. Packaging and Palletizing

Food packaging must be fast, hygienic, and reliable. Robotics automates sealing, labeling, and boxing, significantly speeding up production. Palletizing robots further optimize logistics by stacking products systematically for transport.

4. Quality Control and Safety

High-resolution cameras and AI-integrated robots can detect contamination, mislabeling, or defects in real-time. This not only improves food safety but also ensures compliance with regulatory standards.

5. Cleaning and Hygiene

Food safety regulations demand strict hygiene practices. Specialized cleaning robots can sanitize surfaces, equipment, and processing areas without direct human contact, reducing the risk of contamination.

Benefits of Robotics in Food Processing

- Efficiency: Robots reduce processing times and increase output.

- Consistency: Uniform cutting, packaging, and sorting ensure product quality.

- Cost-effectiveness: Lower labor costs and reduced waste save money long term.

- Safety: Robots take over dangerous or unhygienic tasks, protecting workers.

- Scalability: Robotics allows companies to quickly adjust to market demand.

Challenges of Robotics in the Food Industry

While robotics offers many benefits, challenges remain. High installation costs, complex maintenance, and the need for skilled operators can limit adoption. Small and medium-sized enterprises may find it difficult to invest in robotics compared to larger corporations. However, as technology advances, costs are gradually decreasing, making robotics more accessible.

The Future of Robotics in Food Processing

The future of food processing is smarter, faster, and more sustainable. With the integration of artificial intelligence, machine learning, and robotics, companies will be able to predict demand, optimize supply chains, and deliver healthier, safer products. Robots will not only improve efficiency but also help achieve sustainability goals by reducing waste and conserving resources.

Conclusion

The rise of robotics in food processing is more than a trend—it is a revolution shaping the future of the food industry. From sorting and packaging to hygiene and safety, robots are redefining efficiency and quality standards. While challenges exist, the potential benefits far outweigh the risks, making robotics an essential part of modern food production.

Moonpreneur is on a mission to disrupt traditional education and future-proof the next generation with holistic learning solutions. Its Innovator Program is building tomorrow’s workforce by training students in AI/ML, Robotics, Coding, IoT, and Apps, enabling entrepreneurship through experiential learning.

Related Blogs:

- AI-Enhanced Robotics: The $124 Billion Revolution Reshaping Industry and Labor

- How to Introduce Robotics to Kids Ages 7-8 Years: Activities, Projects & More

- Aibo Robot Dog – The Future of AI and Robotics

- Robotics for 9-Year-Old – Fun and Educational Guide

- The Rise of Soft Robotics: Revolutionizing Automation for the Future

- Top 10 Robotics Games For Kids